Achieving jidoka, therefore, requires building and improving systems by hand until they are reliable and safe. We will use these initiatives and develop our human resources to make ever-better cars that will be cherished by customers.įor Toyota, jidoka means that a machine must come to a safe stop whenever an abnormality occurs. Thoroughly honing these strengths is essential for Toyota's future survival. TPS and its approach to cost reduction are the wellsprings of competitive strength and unique advantages for Toyota.

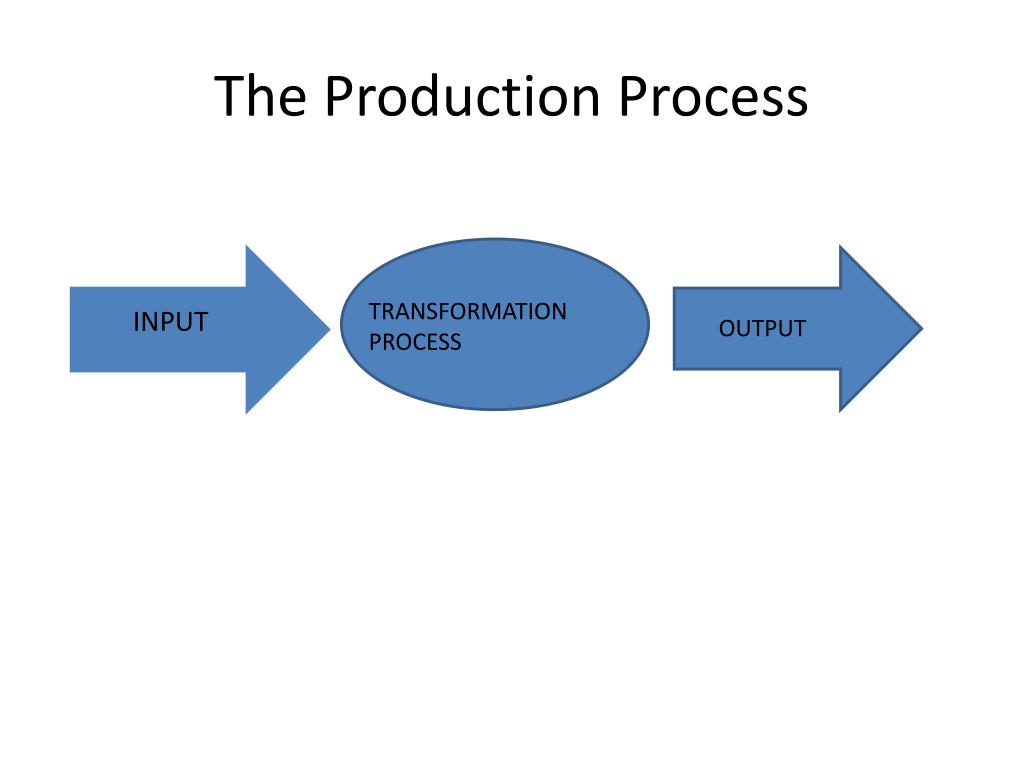

The Toyota Production System (TPS) was established based on two concepts: "jidoka" (which can be loosely translated as "automation with a human touch"), as when a problem occurs, the equipment stops immediately, preventing defective products from being produced and the "Just-in-Time" concept, in which each process produces only what is needed for the next process in a continuous flow.īased on the basic philosophies of jidoka and Just-in-Time, TPS can efficiently and quickly produce vehicles of sound quality, one at a time, that fully satisfy customer requirements. This production control system was established based on many years of continuous improvements, with the objective of making the vehicles ordered by customers in the quickest and most efficient way, in order to deliver the vehicles as swiftly as possible. Toyota Motor Corporation's vehicle production system is a way of making things that is sometimes referred to as a "lean manufacturing system," or a "Just-in-Time (JIT) system," and has come to be well known and studied worldwide. A production system based on the philosophy of achieving the complete elimination of all waste in pursuit of the most efficient methods.

0 kommentar(er)

0 kommentar(er)